Procurement Compliance Without Slowing Operations

Compliance that does not slow procurement? It is not only possible, it is essential. Procurement often gets caught between safety and speed. We built a practical guide to achieve risk‑based controls, routes to market that fit the situation, and evidence captured as you work. The result is fewer handoffs, faster decisions, and stronger assurance.

If you would value a short readiness review, we are here to help. Message us to discuss your current bottlenecks.

Ensuring Procurement Compliance Without Slowing Operations

How to meet regulatory requirements while keeping procurement agile and efficient.

Executive overview

Compliance and speed are often framed as opposing forces in procurement. One protects the organisation from legal, financial, and reputational harm; the other powers growth, resilience, and customer delivery. The reality is that the most effective procurement teams achieve both at once. They design controls that are proportionate to risk, embed those controls into everyday tools and routines, and use data to continuously remove friction. Instead of adding layers of review, they make the right way the easy way.

This paper offers a practical blueprint for leaders who want to raise compliance without slowing the business. It sets out a risk‑based approach to policy and governance, a modern process design that keeps cycle times short, and a technology and data stack that enforces rules automatically while preserving user experience. You will also find a thirty–sixty–ninety‑day plan, a one‑page policy outline, a role and responsibility map, and a simple scorecard that balances compliance and agility.

The guidance is written for organisations across sectors and sizes, and is applicable in both private and public contexts. It avoids jargon, favours simple language, and focuses on moves you can make immediately.

1) Why compliance and speed are not opposites

Many teams experience compliance as rework, delay, or rigid gatekeeping. That is usually a symptom of controls that are either too heavy for the risk involved, or too separate from day‑to‑day work.

When controls are proportionate and embedded, three positive effects appear:

1. Fewer handoffs, fewer reworks.

Clear rules, standard templates, and thresholds reduce back‑and‑forth with Legal, Finance, and Risk.

2. Faster, more confident decisions.

Clear rules, standard templates, and thresholds reduce back‑and‑forth with Legal, Finance, and Risk.

3. Better outcomes, fewer surprises.

Early checks prevent issues that are expensive to fix later, such as sanctions breaches, contract gaps, or supplier disputes.

The aim is not to do more checking; it is to design a process in which the safest route is the most convenient route.

2) The modern compliance stack for procurement

A resilient operating model combines policy, process, people, and technology in a single, coherent system.

- Policy architecture. A short, principle‑based procurement policy supported by practical playbooks, procedures, and templates. Policy is stable; playbooks are living documents.

- Risk‑based controls. Controls vary by spend value, category risk, supplier risk, and jurisdictional exposure. High risk gets depth; low risk gets speed.

- Embedded technology. Procure‑to‑pay and contract lifecycle systems enforce rules automatically: budgets, delegations, supplier due diligence, and audit trails.

- Data discipline. Clean supplier and contract master data; standard taxonomies; reliable spend analytics; and a single source of truth for approvals and evidence.

- People and culture. Clear roles, simple training, and a habit of learning from exceptions rather than blaming individuals.

3) Ten core principles to raise compliance without slowing the business

Principle 1: Segment by risk, not only by spend

Spending thresholds alone are a blunt instrument. Segment by four lenses: value, category risk, supplier risk, and jurisdictional risk. For example, low‑value software subscriptions may require stronger checks than higher‑value stationery because of data and security exposure. Use a simple matrix to define which controls apply where. Keep it to three risk tiers to avoid complexity.

Principle 2: Standardise what repeats; create space where judgement matters

Write short, principle‑based rules and supplement them with checklists and standard templates for specifications, market soundings, requests for quotation, evaluation models, and contracts. Where the market is dynamic or innovation is required, provide discretion within clear boundaries. Empower category managers to choose methods that fit the market, provided they capture an audit trail that explains the choice and the outcome.

Principle 3: Build controls into the tools, not into extra steps

Use your systems to enforce guardrails automatically. Examples include: budget checks that happen at requisition; mandatory conflict of interest declarations at the start of each event; supplier due diligence and sanctions screening at onboarding and before award; template selection that matches the chosen route to market; and automated three‑way matching at invoice. When control happens in the background, people experience less friction.

Principle 4: Pre qualification and dynamic supplier pools

Maintain a living register of pre‑qualified suppliers by category, with clear entry and renewal criteria, including ownership information, financial health, ethical standards, and safety records. Use dynamic onboarding so that suppliers can update their information in real time. For frequently purchased, low‑risk goods and services, operate rotating panels with mini‑competitions that can be launched in hours rather than weeks.

Principle 5: Lightweight governance that respects time

The best delegations of authority are concise and unambiguous. Avoid overlapping limits and unnecessary escalation chains. Require dual approval only where the risk warrants it. Publish turnaround standards for approvals, measured in working hours. If an approver consistently misses the standard, route to an alternate and trigger a coaching conversation, not a work stoppage

Principle 6: Intelligent automation where it truly helps

Automate repetitive checks such as duplicate invoice detection, out‑of‑contract spend alerts, missing receipt prompts, and simple price‑quantity matches. Use business rules to flag exceptions for humans rather than forcing humans to review every item. Where appropriate, use machine learning to prioritise anomalies for review, always with human oversight and clear explainability. Do not chase complexity for its own sake; the simplest control that works is usually best.

Principle 7: Sourcing methods that fit the situation

Offer a small set of routes to market and make each one easy to use:

- Catalogue buying for standard items with pre‑negotiated prices.

- Request for quotation for straightforward, competitive buys.

- Negotiated procedure for complex services where interview and iteration are needed.

- Reverse auction where price competition can be made transparent and fair.

- Innovation partnership for outcomes where the solution is not yet known.

Each route has a pre‑built evidence pack, so the user does not spend time inventing forms.

Principle 8: Audit readiness by design

Capture the right evidence as you go: decision logs, evaluation notes, approvals, supplier communications, and contract versions. Store it centrally and index it to categories, projects, and suppliers. When an auditor asks for proof, respond in minutes, not weeks. A good test is whether a new team member could, from the record, explain why a decision was the right one at the time.

Principle 9: Culture: explain the “why”, not just the “what”

Adults comply when they understand the purpose and see the benefit. Use short, story‑led training that shows how controls protect the organisation and the individual. Share one page summaries and short videos; avoid long manuals. Create a feedback loop where users can flag friction and propose better ways that still meet the intention of the control.

Principle 10: Balance the scorecard

Measure both safety and speed. Suggested measures include: percentage of spend under contract; policy breach rate; late approval rate; procure‑to‑order cycle time; time to award; proportion of exceptions processed within service standards; reduction in maverick spend; and user satisfaction. Publish the scorecard and discuss it in monthly reviews. What is measured is improved.

4) A one page procurement compliance policy (outline)

Purpose

To obtain goods and services fairly, transparently, and in a manner that delivers value for money while meeting legal and ethical obligations.

Scope

All purchases of goods and services by the organisation, regardless of funding source.

Principles

- Act with integrity, impartiality, and transparency.

- Select suppliers on merit, using evidence and proportionate competition.

- Apply controls according to risk.

- Keep complete and accurate records.

- Manage conflicts of interest openly and promptly.

- Support small and diverse suppliers where appropriate and lawful.

- Protect people, data, and the environment.

Routes to market

Catalogue purchase; request for quotation; negotiated procedure; reverse auction; innovation partnership. Each route has pre‑defined thresholds and evidence requirements.

Delegation of authority

Clear, published financial limits for requisition, contract award, and change control. Dual approval only for defined high‑risk situations.

Supplier due diligence

Identity, beneficial ownership, financial health, ethical standards, safety, data protection, and sanctions alignment, refreshed on a schedule that reflects risk.

Conflicts of interest

Mandatory annual declarations and event‑specific declarations. Any conflict is recorded with a mitigation plan.

Record keeping

All decisions, approvals, communications, and contract versions are stored in the central repository.

Consequences

Breaches may lead to corrective action, including training, process change, or disciplinary steps where warranted.

5) Roles and responsibilities: the three lines of defence

First line – the business and procurement

- Define demand and specifications.

- Run sourcing events and manage suppliers.

- Maintain records and ensure day‑to‑day compliance.

- Own the balanced scorecard for safety and speed.

Second line – risk, legal, finance, and information security

- Set standards and provide advice.

- Approve the policy and playbooks.

- Monitor adherence through sampling and dashboards.

- Support training and complex decisions.

Third line – internal audit

- Provide independent assurance on the design and operation of controls.

- Recommend improvements based on evidence.

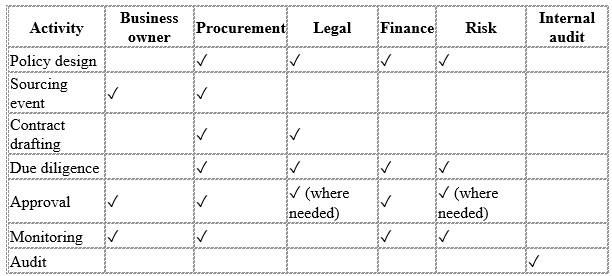

A simple responsibility map helps avoid confusion:

6) A thirty–sixty–ninety day plan

First thirty days: stabilise and see

- Map the current process from request to invoice. Identify delays, handoffs, and duplicate checks.

- Catalogue current policies, templates, and system controls. Remove obsolete documents.

- Clean the top one hundred supplier records for accuracy of names, identifiers, ownership, and banking details.

- Publish a two‑page summary of routes to market and who approves what.

- Start measuring simple cycle times and approval turnaround against a baseline.

Sixty days: embed and simplify

- Implement pre‑qualification for the top five categories by risk and value.

- Configure system‑based checks for budgets, conflicts of interest, and sanctions alignment.

- Replace long manuals with one‑page checklists and short videos.

- Pilot a catalogue for common goods; agree catalogue governance with key suppliers.

- Train approvers on their role, including the expectation to respond within set timeframes.

Ninety days: scale and learn

- Expand pre‑qualification to remaining material categories.

- Introduce automated duplicate invoice detection and missing receipt prompts.

- Launch a monthly review of the balanced scorecard with action‑oriented discussions.

- Establish a simple exception forum that meets weekly for thirty minutes to resolve stuck items and to adjust rules that cause unnecessary friction.

- Publish success stories that show how controls prevented harm while saving time.

7) Category specific tactics

Professional services

- Use clear, outcome‑based statements of work and capped fee models.

- Pre‑qualify for capability and independence, including conflict checks.

- Maintain a record of evaluation justifications for direct awards where continuity is required.

Information technology and software

- Require security and data protection assessments for cloud services.

- Use standard terms for data processing, access rights, and exit.

- Track licence usage to prevent over‑buying and to reduce audit exposure.

Logistics and distribution

- Enforce safety and insurance standards.

- Benchmark rates regularly and use mini‑competitions for lanes.

- Monitor on‑time delivery and damage rates as part of the supplier scorecard.

Marketing and media

- Separate strategy, creative, production, and media buying where it makes sense to improve competition and transparency.

- Require time‑stamped approvals of creative and media plans.

- Where rebates or incentives exist, ensure transparent treatment in contracts and reporting.

Capital projects

- Strengthen change control and require full documentation for variations.

- Use independent quantity and quality verification for milestone payments.

- Preserve site instructions, daily records, and testing certificates in a central repository.

8) Supplier relationships that strengthen compliance

Controls improve when suppliers are partners in the process. Publish a supplier code of conduct, go beyond paper by discussing expectations during onboarding, and provide a clear route for suppliers to raise concerns without fear. Share your evaluation criteria and feedback after an award. Where possible, help small and diverse businesses meet entry requirements through training and phased onboarding. Transparency builds trust and improves competition.

9) Exception handling that protects speed and integrity

Exceptions are not failures; they are signals. Design a simple pathway:

- The requester proposes an exception with a short, reasoned case.

- A cross‑functional panel meets weekly for thirty minutes to decide, guided by principles.

- Decisions and rationales are recorded, and temporary approvals have expiry dates.

- Repeated, similar exceptions trigger a rules update to remove unnecessary friction.

This approach prevents queues and preserves the audit trail that shows why a non‑standard route was still the right route.

10) A practical evidence pack

For each sourcing route, pre‑assemble a short set of documents:

- Business need and options analysis.

- Route‑to‑market justification linked to the risk tier.

- Market engagement record and clarifications.

- Evaluation plan and scoring sheets.

- Approval record with dates and names.

- Due diligence summary.

- Signed contract and change log.

- Supplier performance plan and first ninety‑day check.

Store everything in the central repository with consistent naming and version control. If a new person joined tomorrow, they should be able to understand the full storyline without asking for extra emails or side chats.

11) Scorecard: measures that matter

Combine safety and speed into one page.

Safety

- Proportion of spend under contract.

- Policy breach rate by value and category.

- Results of sampling on due diligence, conflicts of interest, and record completeness.

- Late detection of duplicate invoices or out‑of‑contract spend

Speed

- Average time from request to order by risk tier.

- Time to award by route to market.

- Approval turnaround against the published standard.

- Percentage of exceptions resolved within one week.

Experience and value

- User satisfaction with the process.

- Supplier satisfaction with fairness and clarity.

- Savings and cost avoidance realised versus plan.

- Reduction in disputes and claims.

Review monthly, agree three actions, and track the effect the following month. Keep the discipline light but consistent.

12) Short case vignette

A diversified manufacturing group faced regular audit findings for incomplete records and frequent complaints about slow approvals. The team undertook a ninety‑day reset. They redesigned the policy into a six‑page document supported by playbooks, implemented catalogue buying for low‑risk items, introduced automatic budget checks and conflict of interest declarations, and set a forty‑eight‑hour approval standard with alternates.

Within six months, the proportion of spend under contract rose from fifty to seventy‑eight percent, average time from request to order fell from thirteen days to five, and audit exceptions reduced by two‑thirds. Supplier satisfaction improved, particularly for smaller firms, because timelines were clearer and feedback was routinely provided. The team kept improving through a weekly exception forum, which removed three redundant steps that had survived from older processes.

13) Frequently asked questions

Is strict compliance compatible with innovation?

Yes. Use the innovation partnership route where outcomes are defined but solutions are not. Protect fairness with transparent criteria, staged gates, and independent reviews.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Will more automation lead to less judgement?

Well‑designed automation removes repetitive checks so humans can focus on the decisions that require judgement. Keep people in the loop for exceptions and high‑risk cases.

How should we treat suppliers that fail due diligence but are critical to operations?

Use risk mitigation plans with time‑bound corrective actions, such as independent audits, enhanced reporting, or limited scope while remediation is underway. Escalate to the executive team where the risk cannot be mitigated.

Do small organisations need the same controls as large ones?

No. Keep the same principles but simplify the artefacts. Use fewer thresholds, one approval stage, and a light evidence pack. The aim is clarity, not bureaucracy.

14) Conclusion: make the right way the easy way

Compliance without delay is achievable. It requires proportionate rules, controls embedded in tools, data that tells the truth, and a culture that values both safety and speed. Start small, fix the next bottleneck, and celebrate every time a control prevents harm while saving time. Over a year, those marginal gains compound into a resilient, respected procurement function that the business actively seeks out rather than avoids.

Call to action

Duja Consulting helps organisations build procurement functions that are compliant by design and fast by nature. From policy redesign and playbooks to system configuration, supplier due diligence, and audit‑ready evidence packs, we combine practical experience with forensic discipline. If you would value a conversation or a short readiness review, we would be pleased to help.

Contact: Madi du Toit, Chief Executive Officer, Duja Consulting

Email: info@dujaconsulting.co.za

Website: www.dujaconsulting.co.za

Appendix A: One page checklist for requesters

- Have you described the need in outcomes, not only features?

- Which risk tier applies (value, category, supplier, jurisdiction)?

- Which route to market applies?

- Have you declared any conflicts and recused yourself where needed?

- Is the budget available and approved?

- Are pre‑qualified suppliers available?

- Have you kept a record of clarifications and decisions?

- Are you using the correct contract template?

- Have you planned a start‑up meeting and first ninety‑day review?

Appendix C: Example playbook contents

- Does the route to market fit the risk tier?

- Is the specification clear and fair?

- Are evaluation criteria objective and applied consistently?

- Are due diligence checks complete and explained?

- Is there a clear audit trail of decisions?

- Have conflicts been disclosed and addressed?

- Is the contract complete, with change control defined?

- Are data protection and safety obligations covered?

- Will this decision withstand public and audit scrutiny?

Appendix C: Example playbook contents

- Route to market decision tree with three risk tiers.

- Pre‑qualification criteria by category.

- Standard evaluation methods and weights.

- Contract templates with modular clauses for data, safety, and sustainability.

- Change control protocol and variation forms.

- Supplier performance review template with on‑time delivery, quality, and cost measures.

- Guide for managing and recording market soundings.